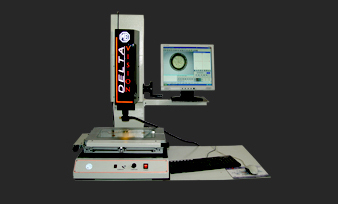

Video Vision Inspection System

The VideoVision Inspection System integrates state-of-the-art high quality optics and video with versatile hardware & software to meet the most demading needs of non-contact inspection and measurement. This is achieved by combining the strengths of a traditional profile projector, toolmaker's microscope, and CMM in one complete compact package. The design has been optimised for stable, long-term performance in the most demanding environments.

DeltaVision can also be used for high end metallurgical microscopic examinations using high resolution CCD camera, high precision parafocal zoom lens, coupled with high resolution monitors, either colour or monochrome, depending on user requirements. The fibre optics based ring light provides variable lighting, which enables examinationof highly magnified surfaces with great accuracy, under varying light conditions. Several system configurations are available to suit specific applications and budgets.

Features

- High precision zoom parafocal optics.

- High Resolution CCD monochrome/colour camera and monitor.

- Precision worktable with X & Y-axis traverse.

- Accuracy of under 0.004 mm over the entire traverse.

- Measuring resolution of 0.001 mm.

- Dedicated Data Processor for geometric functions like radii, distances skew alignment and angles, with RS232 port for data output.

- Under stage lighting for profile measurements

- Fibre Optics based ring light ilumination system provides bright, even and cool surface illumination to the part being measured/examined, and ensures crisp, clear images on the monitor.

- Electronic graticule generator with changeable white and black lines, enables users to align & pickup edge coordinates to calculate various geometric configurations.

- Can be coupled with image capture and transfer software to send images to a PC. The image can be saved in standard TIFF, BMP, GIF, etc. formats for printing, etc.

Applications and System Specifications

- Electronic Inspection: PCB Industry and artwork.

- Food & Packaging Inspection: Automated food inspection system.

- Image Cataloguing: For visual cataloguing.

- Semiconductor Inspection: Water inspection systems.

- Medical Visualisation: Medical device components and cell analysis.

- Engineering Application: Tooling & gauges, machined parts measurement & defect analysis.

- Chemical & Plastic Industry: Chemically machined, injection moulded, plastic, glass, ceramic, rubber and composite parts inspection.

- Optics: Precision Zoom Parafocal Lens that provides a system magnification ranging from 30 to 240x

- Camera: High Resolution Monochrome Camera

- Video Equipment: High Resolution TV Monitor

- Profile: Backlight Pad

- Surface Illumination: Fibre Optics Cold Ring Light fitted onto Zoom Lens

- Traverse: X Axis : 150 mm

Y Axis : 100 mm - Focussing Traverse : Z Axis : 150 mm

- Measurement : Linear Transducers

- Resolution : 0.001 mm

- Linear Accuracy : 0.005 mm on X and Y traverse (overall)

- Workstage Top Dimension : Approx. 350 x 250 mm

- Workstage Glass Dimension : Approx. 180 x 150 mm

- Load Capacity : Max 20 Kgs. Evenly distributed.

- Linear Transducers : 1 each for X & Y traverse. Resolution: 0.001 mm

- Data Processor : DP8 Ver 2.0

- Printer

Electric Energy 220 V Single Phase AC Supply on 3 Pin 15 A Socket is required

Optional

- Magnification from 15x - 40x. Ultra zoom upto 1000x

- Colour Camera and Colour Monitor

- Z-Axis Measurement by single axis DRO

- Frame-grabber card for the computer to save and print images

- PC-based measurement system with a powerful windows-based software with Video Edge Detection using sub pixel based gauging to easily measure any feature seen within the field of view without movement of the workstage

- Rotary table with 120 mm dia. and 1 deg. graduation